A local authority has been sentenced after a school technician lost a finger while operating a machine.

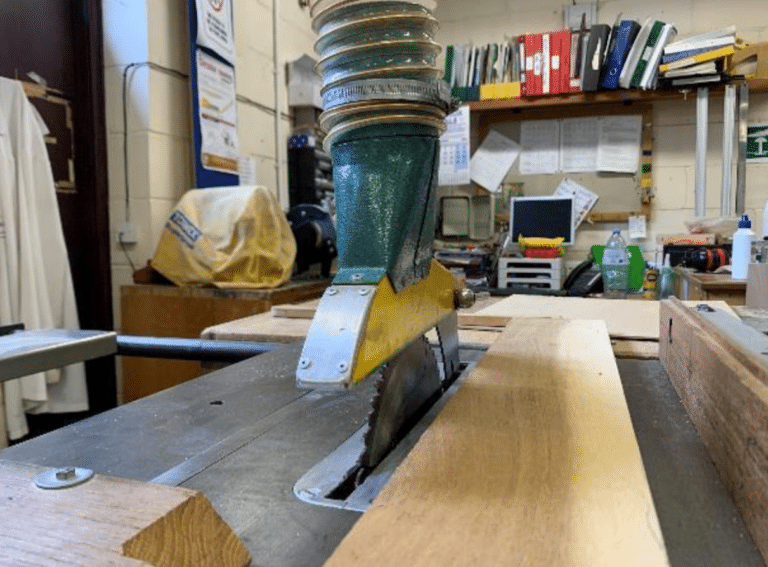

A school technician at The Forest School in Horsham, lost his right index finger when it was sliced off by a circular bench saw on 13 June 2022.

The 29-year-old, who worked in the design and technology (DT) department, had been operating the saw to cut pieces of wood that were set to be used for a DT lesson. The school technician lost a finger in the accident.

While pushing one of the sheets of wood through the saw, the technician who was 27 at the time, felt a pain in his right index finger and immediately turned off the machine. As he looked down, he saw his finger lying on the bench.

A Health and Safety Executive (HSE) investigation found West Sussex County Council, the local authority in charge of the school, failed to ensure that the technician was trained to use the bench circular saw, as a result the school technician lost a finger. Whilst the technician had used the saw many times previously, he had not been trained on how to use it safely.

West Sussex County Council pleaded guilty to breaching Regulation 9 of the Provision and Use of Work Equipment Regulations 1998. The local authority was fined £16,000, ordered to pay £4,294.60 in costs and a victim surcharge of £190 at Brighton Magistrates’ Court on 3 July 2024.

HSE inspector Russell Beckett said:

Workers must be trained properly when using high risk woodworking such as bench circular saws. This incident could have been prevented had West Sussex County Council provided [the technician] with proper training.

The Provision and Use of Work Equipment Regulations 1998

The above incident where a school technician lost a finger highlights the importance of training and other issues for workers using equipment. The Provision and Use of Work Equipment Regulations 1998, often abbreviated to PUWER, place duties on people and companies who own, operate or have control over work equipment. PUWER also places responsibilities on businesses and organisations whose employees use work equipment, whether owned by them or not. PUWER requires that equipment provided for use at work is:

- suitable for the intended use

- safe for use, maintained in a safe condition and inspected to ensure it is correctly installed and does not subsequently deteriorate

- used only by people who have received adequate information, instruction and training – in the current case, the school technician lost a finger having not received any training in the safe use of the circular saw.

- accompanied by suitable health and safety measures, such as protective devices and controls. These will normally include guarding, emergency stop devices, adequate means of isolation from sources of energy, clearly visible markings and warning devices

- used in accordance with specific requirements, for mobile work equipment and power presses

Some work equipment is subject to other health and safety legislation in addition to PUWER. For example, lifting equipment must also meet the requirements of the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER), pressure equipment must meet the Pressure Systems Safety Regulations 2000 and personal protective equipment must meet the Personal Protective Equipment at Work Regulations 1992 (PPE).

If your business or organisation uses work equipment or is involved in providing work equipment for others to use (e.g. for hire), you must manage the risks from that equipment. This means you must:

- ensure the equipment is constructed or adapted to be suitable for the purpose it is used or provided for

- take account of the working conditions and health and safety risks in the workplace when selecting work equipment

- ensure work equipment is only used for suitable purposes

- ensure work equipment is maintained in an efficient state, in efficient working order and in good repair

- where a machine has a maintenance log, keep this up to date

- where the safety of work equipment depends on the manner of installation, it must be inspected after installation and before being put into use

- where work equipment is exposed to deteriorating conditions liable to result in dangerous situations, it must be inspected to ensure faults are detected in good time so the risk to health and safety is managed

- ensure that all people using, supervising or managing the use of work equipment are provided with adequate, clear health and safety information. This will include, where necessary, written instructions on its use and suitable equipment markings and warnings

- ensure that all people who use, supervise or manage the use of work equipment have received adequate training, which should include the correct use of the equipment, the risks that may arise from its use and the precautions to take

- where the use of work equipment is likely to involve a specific risk to health and safety (eg circular saw machine), ensure that the use of the equipment is restricted to those people trained and appointed to use it – in the current case where the school technician lost a finger, the local authority should have restricted access to those workers who had received training.

- take effective measures to prevent access to dangerous parts of machinery. This will normally be by fixed guarding but where routine access is needed, interlocked guards (sometimes with guard locking) may be needed to stop the movement of dangerous parts before a person can reach the danger zone. Where this is not possible, such as with the blade of a circular saw, it must be protected as far as possible and a safe system of work used. These protective measures should follow the hierarchy laid down in PUWER regulation 11(2) and the PUWER Approved Code of Practice and guidance or, for woodworking machinery, the Safe use of woodworking machinery: Approved Code of Practice and guidance

- take measures to prevent or control the risks to people from parts and substances falling or being ejected from work equipment, or the rupture or disintegration of work equipment

- ensure that the risks from very hot or cold temperatures from the work equipment or the material being processed or used are managed to prevent injury

- ensure that work equipment is provided with appropriately identified controls for starting, stopping and controlling it, and that these control systems are safe

- where appropriate, provide suitable means of isolating work equipment from all power sources (including electric, hydraulic, pneumatic and gravitational energy)

- ensure work equipment is stabilised by clamping or otherwise to avoid injury

- take appropriate measures to ensure maintenance operations on work equipment can be carried out safely while the equipment is shut down, without exposing people undertaking maintenance operations to risks to their health and safety

When providing new work equipment for use at work, you must ensure it conforms with the essential requirements of any relevant product supply law (for new machinery this means the Supply of Machinery (Safety) Regulations 2008). You must check it:

- has appropriate conformity marking and is labelled with the manufacturer’s details

- comes with a Declaration of Conformity

- is provided with instructions in English

- is free from obvious defects – and that it remains so during its working life

If you require advice on health and safety in your workplace, please contact one of the Ashbrooke team.