Transport safety failures resulted in a company being fined £380,000 after a bus caused life-changing injuries to one of its employees when they were between a reversing bus and a stationary vehicle.

The employee of Stagecoach Devon Limited was working at the company’s Torquay depot on the morning of 3 October 2019. Due to space limitations, buses often had to reverse to be able to leave the depot in readiness for the day’s work. The sole banksman, who would direct vehicles, was occupied at the top of the depot where most buses were parked.

As a result, it became custom and practice for the bus drivers at the front of the depot to reverse without a banksman, or to assist each other when reversing, despite not being trained as banksmen.

The injured employee, who was caught between a reversing bus and a stationary vehicle, suffered compound multiple fractures of his arm requiring six titanium plates and 65 metal staples between his wrist and elbow.

An investigation by the Health and Safety Executive (HSE) found that Stagecoach failed to put a suitable and sufficient risk assessment in place.

This should have identified the risks inherent in the bus parking layout and action could have been taken to remove the need to reverse or mitigate the risks from reversing. For example, changing the parking layout, providing a sufficient number of trained banksmen for peak times, and improved segregation of vehicles and pedestrians.

At Plymouth Magistrates Court Stagecoach Devon Limited of Stockport, pleaded guilty to breaching Section 2(1) of the Health and Safety at Work etc. Act 1974. The company was fined £380,000 and ordered to pay costs of £18,000.

“Those in control of work have a responsibility to devise safe methods of working and to provide the necessary information, instruction and training to their workers in the safe system of work.

“If a suitable safe system of work had been in place prior to the incident, the life changing injuries sustained by the employee could have been prevented.”

HSE Inspector James Collins

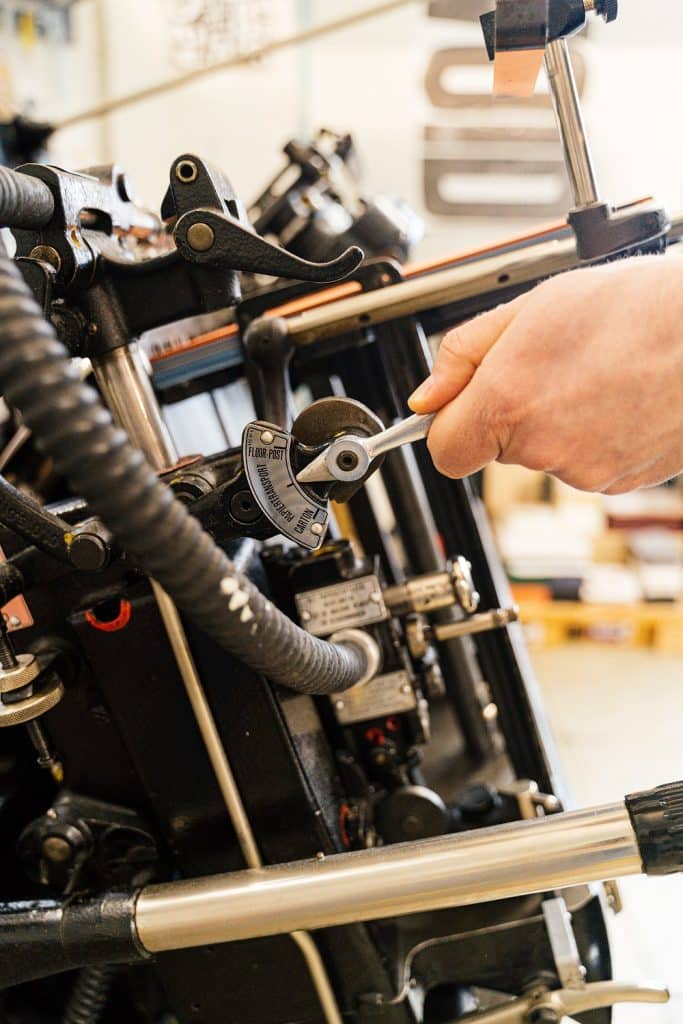

Employers who operate depots must ensure that a suitable and sufficient risk assessment is undertaken covering the transport risks to ensure transport safety failures do not occur. When considering the risks from vehicle manoeuvring, employers must ensure that vehicles have large enough windscreens (with wipers where necessary) and external mirrors to provide an all-round field of vision. It is often worthwhile adding extra mirrors to reduce blind spots for drivers. Side mirrors can allow drivers of larger vehicles to see cyclists and pedestrians alongside their vehicles and can be effective in improving visibility around the vehicle from the driving position. These mirrors are fitted to larger road-going vehicles as standard.

Drivers should not place items in the windscreen area or in the way of mirrors or monitors, where they might impede visibility from the driving position. The area of the windscreen that is kept clear by the wipers should not be obscured, and nor should the side windows. Windows and mirrors will also normally need to be kept clean and in good repair. Dirt or cracks can make windows or mirrors less effective.

Some types of vehicles (such as straddle carriers, large shovel loaders and some large quarry vehicles) often have poor visibility from the cab. Visibility can be poor to the side or front of a vehicle as well as behind and loads on vehicles can severely limit the visibility from the driving position.

Lift trucks and compact dumper vehicles in particular can have difficulty with forward visibility when they are transporting bulky loads. Employers should recognise these risks in their risk assessment and think about ways to minimise them.

Closed-circuit television (CCTV) may help drivers to see clearly behind or around the vehicle. CCTV can cover most blind spots and the cost of fitting CCTV systems has fallen since the technology was first developed. Companies who have fitted CCTV have found that it can reduce the number of reversing accidents, so the systems usually pay for themselves in a few years.

Colour systems can provide a clearer image where there is little contrast (for example, outside on an overcast day). However, black-and-white systems normally provide a better image in lower light or darkness, and usually come with infra-red, which can be more effective than standard cameras at night.

Monitors should have adjustable contrast, brightness and resolution controls to make them useful in the different light conditions in which they will be used. Drivers may need to use a hood to shield any monitor from glare.

If possible, fit the camera for a CCTV system high up in the middle of the vehicle’s rear (one camera), or in the upper corners (two cameras). This will provide a greater field of vision and a better angle for the driver to judge distance and provide. It also keeps the camera clear of dust and spray, and out of the reach of thieves or vandals.

However, CCTV systems do have some limitations which employers should consider:

- If the vehicle leaves a darker area to a more strongly lit area (for example, driving out of a building) the system may need time to adjust to the brightness.

- A dirty lens will make a camera much less effective.

- Drivers may find it difficult to judge heights and distances.

Drivers should not be complacent about safety even with CCTV systems installed as this can result in transport safety failures. They should be trained in proper use of the equipment and employers have a duty to provide such training and instruction.

Reversing alarms may be drowned out by other noise or may be so common on a busy site that pedestrians do not take any notice. It can also be hard to know exactly where an alarm is coming from, and people who are less able to hear are also at greater risk. Alarms can also disturb nearby residents. However, reversing alarms may be appropriate (based on the risk assessment) but might be most effectively used with other measures, such as warning lights.

Additional advice on transport safety can be found in the HSE Guide to workplace transport safety (HSG 136, 2014) which is available free on the website.

If you require health and safety advice or support for your business, please contact one of the Ashbrooke team.